Metering-type Masterbatch Mixer for Injection Molding Machines

Functionality & Benefits

1.Precise Metering: Our mixer features advanced metering capabilities that enable precise control over the amount of colorant or additive being mixed into the plastic pellets. This ensures consistent coloration throughout the production process, reducing waste and enhancing product quality.

2.High Mixing Accuracy: The mixer incorporates high-performance mixing mechanisms that ensure thorough and uniform mixing of the colorant with the Plastic Material. This results in a smoother, more consistent color finish in the final product. 3.Automation & Efficiency: The metering-type mixer is designed for seamless integration with injection molding machines, enabling automated color mixing. This significantly reduces manual intervention, increases production efficiency, and minimizes the risk of human error.

4.Versatility & Flexibility: Our mixer can be configured to handle various types of colorants and additives, making it suitable for a wide range of applications. It also allows for easy adjustment of mixing parameters, enabling you to adapt to different material types and production requirements.

5.Durability & Reliability: Built with robust materials and precision engineering, our mixer is designed to withstand continuous use and maintain its performance over time. This ensures reliable operation and minimal downtime, contributing to overall production efficiency.

Usage Instructions

1.Setup & Integration: Begin by securely integrating the metering-type masterbatch mixer with your Injection Molding Machine. Ensure that all connections are tight and the mixer is properly aligned for optimal performance. 2.Material Preparation: Prepare the desired colorant or additive according to your production requirements. Ensure that it is in the correct form and quantity for mixing with the plastic pellets.

3.Setting Parameters: Adjust the metering settings of the mixer to achieve the desired color concentration. This involves setting the correct metering rates and mixing times based on the type of material and colorant being used.

4.Starting the Mixing Process: Once the parameters are set and the material is ready, activate the mixer. It will begin metering the colorant into the plastic pellets and mixing them thoroughly. Monitor the process closely to ensure smooth operation and consistent mixing.

5.Monitoring & Adjustment: During the mixing process, regularly check the color consistency and adjust the metering settings if necessary. This ensures that the desired color is achieved and maintained throughout the production run.

6.Maintenance & Cleaning: After use, clean the mixer thoroughly to remove any residual colorant or plastic material. Perform regular maintenance checks to ensure the mixer is in good working condition and ready for the next production cycle.

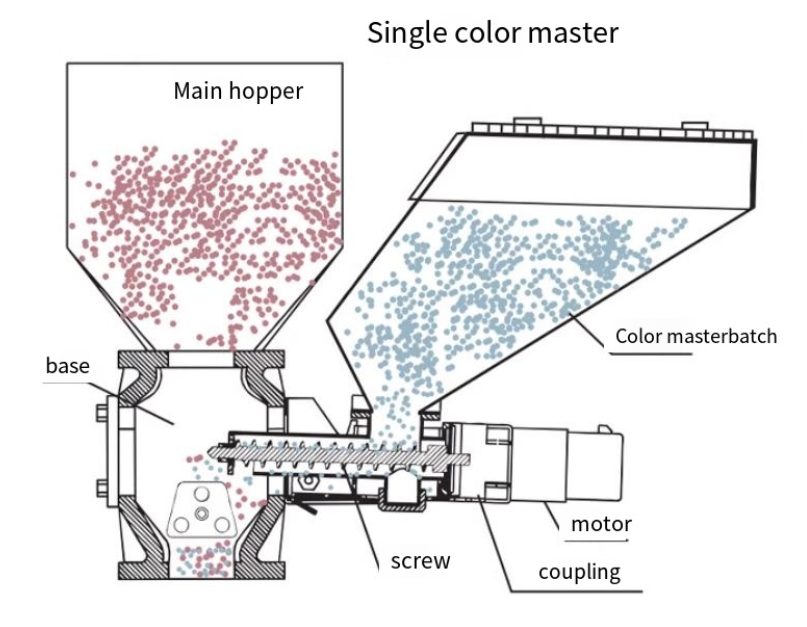

Features: The metering color mother machine adopts PLC color touch screen controller to calculate, measure accurately and output the range of metering color mother machine and Injection molding machine signal synchronization, with formula storage and reading function, can be called to start the machine with metering function, automatically monitor the color masterbatch or add situation, and automatically adjust to the accumulation density of raw materials when the metering part can be removed from the base without leakage, bottom There is a visible material window device on the side of the seat and hopper, which is easy to observe the stable operation of raw materials and ensure the continuity of the production of the injection molding machine. Quantitative feeding can be realized by using the metering scale to control the mixing process, accurate measurement and stable transportation, humanized design, simple operation. Machine performance is stable, modular assembly structure, can change or clean screw and sleeve, with forced cleaning function to facilitate color change masterbatch, screw adopts chrome plating treatment, can be applied to extruder and injection molding machine and blow film mode

As a trusted supplier in the industry, we offer a comprehensive range of Injection Molding Machines, Auxiliary Machines, and injection Molds to meet the diverse needs of our clients.

Our Injection Molding Machine is designed for precision and efficiency, ensuring high-quality outputs in every production cycle.Coupled with our Auxiliary machine, Injection Machine Electric Motor,Injection Machine Nozzle. They enhance the overall performance of the molding process, our solutions are tailored to boost productivity and reduce downtime. Additionally, our Injection Mold is precision-crafted to ensure consistency and accuracy in the finished products.

Whether you're looking to upgrade your existing equipment or establish a new production line, we have the perfect solution for you. Contact us today to learn more.