Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Specialized injection molding machines are precision engineering solutions tailored to produce a wide array of Plastic Products, fulfilling the demands of various industries. These machines are designed to offer flexibility, efficiency, and cost-effectiveness in the manufacturing process.

These specialized machines support customization to ensure precise specifications are met for every project. Whether it's a unique design, specific material requirements, or strict quality standards, these machines can be tailored to deliver exceptional results.

Range of Products:

Small Items:

Medium-sized Plastic Products:

Large Plastic Products:

Precision and Efficiency:

With advanced technology and precise controls, specialized injection molding machines ensure high-quality products with minimal waste. They are capable of handling complex shapes, detailed finishes, and multi-component molds.

By optimizing the production process and reducing material waste, these machines offer a cost-effective solution for mass production of plastic products. The customization options also help manufacturers avoid unnecessary expenses on unsuitable machinery.

Specialized injection molding machines find applications in various industries, including automotive, electronics, consumer goods, medical, and aerospace. Their versatility and adaptability make them a valuable asset for any manufacturer requiring plastic products in varying sizes, shapes, and materials.

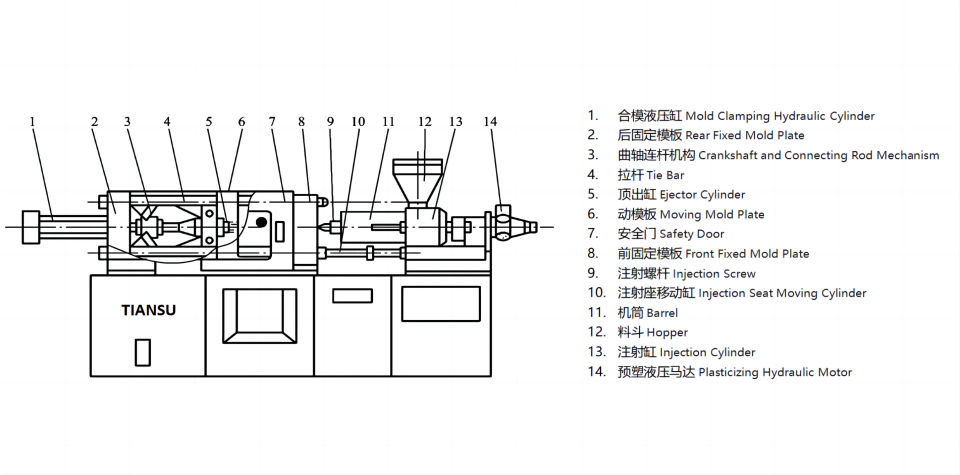

CLAMPING UNIT

INJECTION UNIT

HYDRAULIC UNIT

ELECTRONIC UNIT

Injection molding machine factory interior scene

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.