Automatic Mold Temperature Controller

Advantages

1.Rapid Heating Speed :Our mold temperature controller boasts a rapid heating speed, enabling it to reach the desired temperature swiftly. This feature significantly reduces the wait time, allowing you to initiate the molding process almost immediately, thus enhancing production efficiency.

2.Accurate Temperature Control :Precision is paramount in injection molding, and our controller excels in delivering accurate temperature control. It maintains a consistent and stable temperature throughout the molding process, minimizing fluctuations and ensuring optimal molding conditions for consistent product quality.

3.High Temperature Resistance :Designed to withstand extreme temperatures, our mold temperature controller offers superior durability and reliability. It can handle high operational temperatures without compromising its performance, ensuring long-term stability and reduced maintenance requirements.

4.Automatic Ventilation: Effective heat dissipation is crucial for maintaining optimal performance. Our mold temperature controller features automatic ventilation, which automatically removes excess heat and moisture to prevent overheating and ensure a stable operating environment.

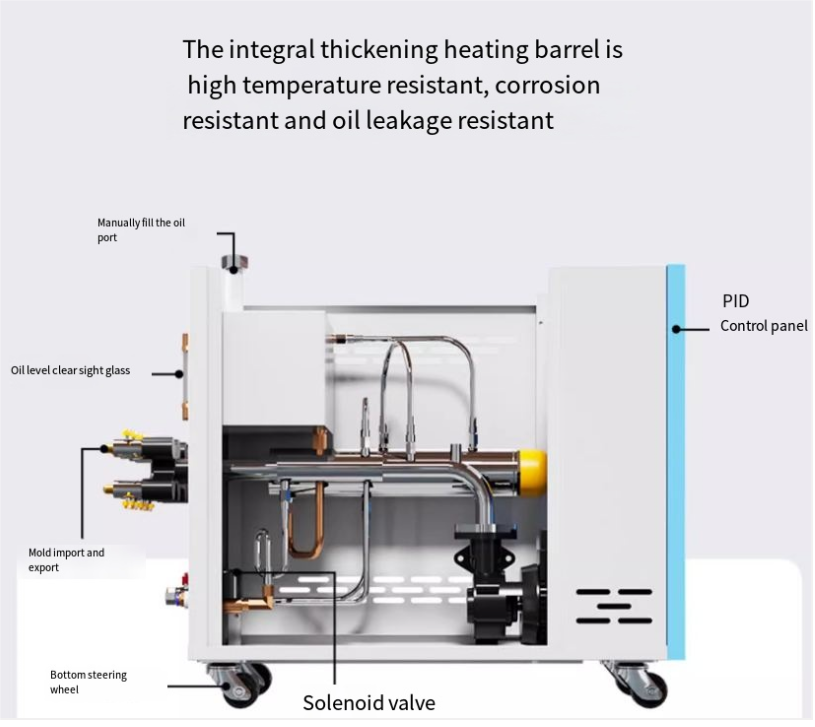

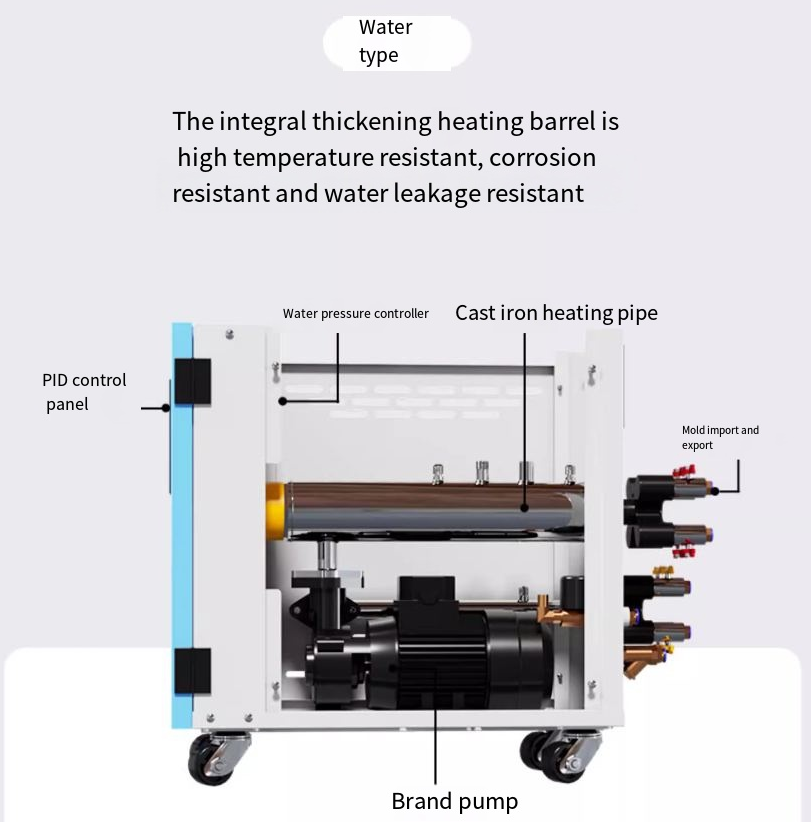

5.High-Quality Heating Elements: The heating elements of our mold temperature controller are of the highest quality, providing uniform and efficient heat distribution. They are durable and designed to last, minimizing the need for replacements and contributing to the overall cost-effectiveness of the machine.

Usage Instructions

1.Set Desired Temperature :Before commencing operation, use the control panel to set the desired temperature for the mold. Adjust the temperature settings according to the specific requirements of your molding process.

2.Connect to Mold System Securely connect the mold temperature controller to the mold system, ensuring all connections are tight and free from leaks. This ensures efficient heat transfer and prevents any potential issues arising from improper installation.

3.Turn on Power Supply :Once the connections are verified, turn on the power supply to the mold temperature controller. Allow it to warm up gradually, reaching the preset temperature.

4.Monitor & Adjust as Needed :Throughout the molding process, continuously monitor the temperature displayed on the control panel. If necessary, make minor adjustments to maintain the desired temperature. This ensures consistent molding conditions and optimal product quality.

5.Power Off & Clean After Use: After completion of the molding process, turn off the power supply to the mold temperature controller. It is recommended to clean the unit regularly to remove any dust or debris that may have accumulated during operation. This helps maintain the performance and longevity of the controller.

With its rapid heating speed, accurate temperature control, high temperature resistance, automatic ventilation, and high-quality heating elements, our mold temperature controller is an ideal solution for injection molding applications. Follow the usage instructions carefully to ensure optimal performance and extend the service life of your machine.

As a trusted supplier in the industry, we offer a comprehensive range of Injection Molding Machines, Auxiliary Machines, and injection Molds to meet the diverse needs of our clients.

Our Injection Molding Machine is designed for precision and efficiency, ensuring high-quality outputs in every production cycle.Coupled with our Auxiliary machine, Injection Machine Electric Motor,Injection Machine Nozzle. They enhance the overall performance of the molding process, our solutions are tailored to boost productivity and reduce downtime. Additionally, our Injection Mold is precision-crafted to ensure consistency and accuracy in the finished products.

Whether you're looking to upgrade your existing equipment or establish a new production line, we have the perfect solution for you. Contact us today to learn more.