Injection Molding Mold Temperature Controller

1. Product Definition:

The Injection Molding Mold Temperature Controller, also known as a Mold Temperature Machine (MTM), is a vital piece of equipment designed specifically for the injection molding industry. It precisely regulates the temperature of the mold during the molding process, ensuring optimal conditions for Plastic Material flow, part quality, and cycle time efficiency.

2. Core Advantages Overview:

- Precision Control: Achieves high-precision temperature regulation, minimizing temperature fluctuations.

- Efficiency Boost: Shortens cooling/heating cycles, enhancing overall production throughput.

- Quality Enhancement: Consistent mold temperatures lead to more uniform product dimensions and improved surface finish.

- Energy Savings: Efficient heat transfer and insulation minimize energy consumption.

- Longevity: Prolongs mold life by reducing thermal stress and preventing material degradation.

3. Unique Features Introduction:

- Intelligent Control System: Equipped with PLC or PID controllers for precise, automatic temperature adjustments.

- Dual-Loop Design: Independent heating and cooling circuits ensure rapid response to temperature changes.

- Eco-Friendly Media: Uses eco-friendly heat transfer fluids, minimizing environmental impact.

- Compact Structure: Space-saving design fits seamlessly into various production lines.

- Easy Maintenance: Modular design allows for quick access and replacement of components.

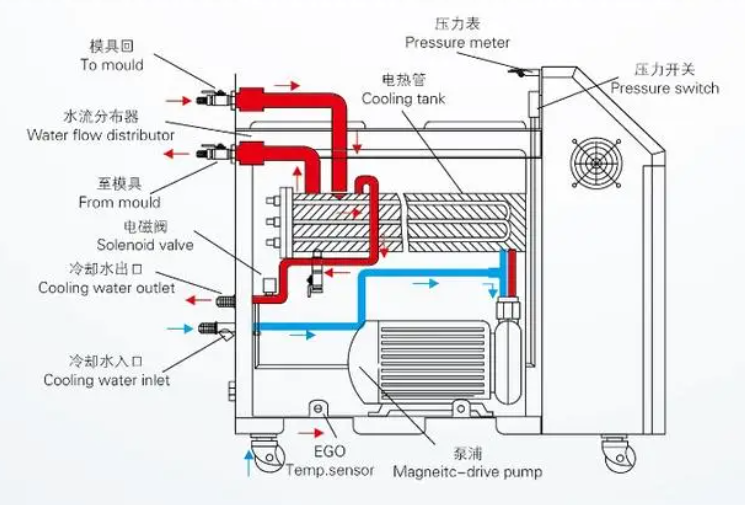

4. Working Principle Brief:

The Mold Temperature Controller circulates a heat transfer fluid (e.g., water, oil) through a closed loop system. The fluid is heated or cooled by an integral heater or chiller unit and then pumped into the mold's cooling channels. Sensors monitor the mold's actual temperature, feeding data back to the control system, which adjusts the heating/cooling output as needed to maintain the desired setpoint.

5. Ideal Installation Position:

The Mold Temperature Controller should be installed in a location close to the Injection Molding Machine but with sufficient space for maintenance access. It's crucial to ensure good ventilation and avoid exposure to direct sunlight or extreme temperatures that could affect the unit's performance. Additionally, the installation site should be level and secure to minimize vibration and noise.

6. Key Role Analysis:

- Process Optimization: Optimizes the molding process by controlling the temperature of the mold, ensuring proper material flow and solidification.

- Quality Assurance: Enhances product quality by reducing warpage, sink marks, and other defects caused by temperature variations.

- Cost Reduction: Minimizes scrap rates and maintenance costs through precise temperature control and extended mold life.

- Sustainability: Supports eco-friendly production practices by using efficient heat transfer and reducing energy waste.

7.Precautions During Use:

- Safety First: Always wear protective gear when working with the machine and follow safety protocols.

- Avoid Overheating: Monitor the fluid temperature to prevent overheating, which could damage the mold or unit.

- Cleanliness: Keep the unit and surrounding area clean to prevent debris from entering the system.

- Regular Inspections: Inspect hoses, fittings, and sensors regularly for leaks or wear.

- Proper Shutdown: Follow the shutdown procedure carefully to avoid damage to the system or mold.

Finally, allow me to introduce our factory, a leading manufacturer specializing in Injection molding machine , Injection molds, and Injection Molding Auxiliary Equipment.

Our Injection Molding Machine is designed for precision and efficiency. Coupled with our Auxiliary machine , Injection Machine Electric Motor, Injection Machine Nozzle . They enhance the overall performance of the molding process. Additionally, our Injection Mold is precision-crafted to ensure consistency and accuracy in the finished products.

We also offer Recycled Plastic Raw Material such as PET, PP, PVC, PS, PA, PE ,ABS pellets. To ensure precise and consistent results, we offer a wide selection of Mold Temperature Control Machines. We offer a wide range of special injection molding machines such as: Water Pail Injection Molding Machine, Fruit Box Injection Molding Machine, Mobile Phone Case Injection Molding Machine,Garbage Can Injection Molding Machine, Injection Molding Machine for Needles, Chair Injection Molding Machine and Basket Injection Molding Machine cater to the needs of our customs, providing them with efficient and cost-effective solutions for mass production.

Whether you're looking to upgrade your existing equipment or establish a new production line, we have the perfect solution for you. Contact us today to learn more.